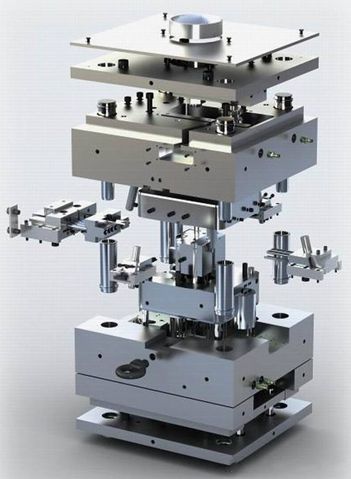

Mould making is a process of designing, developing , and producing moulds that serve as blueprint for producing identical copies of particular object. Mold manufacturing is widely used in many industries, such as automotive, plastic, electronics, and more, to produce parts and products that are durable, cost-effective, and customizable. These molds are made with great accuracy and care. They are used in different manufacturing processes to create copies of products using materials like metal, plastic, ceramic, and composite materials.

How Does Mold Making Work?

Design & Conceptualization:

The journey of Mould Manufacturing starts with detailed design phase, Where professional team of My Design Minds collab to create 3D model with help of CAD (Computer Aided Design) software. Factors such as material selection, dimensional accuracy, and cooling mechanisms are carefully considered.

Material Selection:

Choosing right material for Mould is very essential for long term and efficiency. Factors such as the intended use of the mold, the material of the final product, and the production volume play significant roles in this decision. Common materials include steel for high-volume production molds, aluminum for quicker heat dissipation, and silicone or rubber for flexible mold parts. Our team at My Design Minds ensures that the materials used are of the highest quality to hold high-pressure conditions and repeated use.

Prototyping & Testing:

Before full-scale production, a prototype is developed to validate the design. Techniques like CNC machining and 3D printing help in testing the mould’s functionality. With our expertise, we conduct continuous testing to guarantee optimal performance before mass production begins.

Precision Machining:

When the design is finalized and selected , the Mould is crafted using advanced manufacturing technologies such as CNC milling, EDM (Electrical Discharge Machining), and laser cutting. This ensures high tolerance and fine detailing.

Surface Finishing and Polishing:

Polishing, coating, and texturing are essential steps to enhance the mould’s efficiency and product quality. Treatments such as nitriding, chrome plating, and Teflon coating extend the mould’s lifespan and improve properties. Our commitment to quality ensures that every mould we produce is designed for long-term durability.

Trial run & Approval:

Before going into full production, trial runs are conducted to identify any potential problems with the mold or the molding process. Techniques such as CMM (Coordinate Measuring Machine) inspection and laser scanning are employed. We stand by to global quality standards, ensuring that our moulds deliver unmatched accuracy.

Required Equipment and Machines for Mold Making

Mold making involves using a variety of specialized tools and machines to ensure precision, durability, and efficiency. Each piece of equipment plays a crucial role in shaping, measuring, and finishing molds for different manufacturing processes. Here’s a breakdown of the essential tools and machines used in mold making:

Design and Prototyping Equipment :

Before making a mold, the design process is crucial. CAD (Computer-Aided Design) software helps in creating precise digital blueprints, while CAM (Computer-Aided Manufacturing) software converts these designs into machine-readable instructions. 3D printers are often used to create prototype molds, allowing manufacturers to test designs before full-scale production begins.

Cutting and Shaping Machines :

Once the design is ready, shaping the mold components requires high-precision machines. CNC milling machines are widely used to cut and shape mold parts accurately. For cylindrical parts, a lathe machine is essential. To achieve a fine surface finish and precise dimensions, grinding machines are used. Some mold details are too intricate to be machined traditionally, which is where EDM (Electrical Discharge Machines) come in, allowing for detailed and complex shapes to be formed with ease.

Measuring and Inspection Tools :

Precision is key in mold making, and to ensure accuracy, various measuring tools are used. A Coordinate Measuring Machine (CMM) is important for verifying dimensions. Micrometers and calipers provide precise manual measurements, while optical comparators help inspect fine details and surface finishes, ensuring the mold meets strict quality standards.

Heating and Cooling Equipment :

Temperature control plays a major role in mold making. An injection molding machine is often used to test molds by injecting material into them. To strengthen the mold and enhance its durability, a heat treatment furnace is used to apply controlled heating and cooling. To maintain consistent mold temperature during production, a cooling system with water or oil channels is essential.

Surface Finishing and Polishing Tools :

A mold must have a smooth surface to ensure the final product comes out flawless. Polishing machines help achieve a high-quality finish, while sandblasting machines are used to clean and texture mold surfaces, removing any rough spots or imperfections.

Supporting Equipment :

Several additional machines support the mold-making process. Drilling machines are used to create holes and channels within the mold. Bandsaws and hacksaws help cut raw mold materials into workable sizes. When molds require modifications or repairs, welding machines come in handy for adjustments and reinforcements.

Each of these machines and tools plays a vital role in ensuring that molds are manufactured with precision and efficiency. Investing in the right equipment is essential for producing high-quality molds that meet industry standards.

Why Choose My Design Minds For Mould Manufacturing ?

Experience & Expertise

My Design Minds have year`s of experience in Mould Manufacturing. We have team of professional`s with a deep understanding of materials, machining techniques, and industry-specific requirements.

Good Quality

Our work is a testament to accuracy, innovation, and durability. Every mould we create is subjected to accurate quality control measures to ensure defect-free production. We don’t just manufacture moulds; we craft solutions that redefine precision.

Credibility & Reliability

Our portfolio of successful projects, partnerships with top-tier industries, and long-standing relationships with clients prove our credibility. When you work with My Design Minds, you’re collaborating with a team that values transparency and excellence.

Cutting-Edge Technology

We leverage the latest advancements in CNC machining, automation, and material science to deliver high-performance moulds that meet the highest industry standards.

Our Time is Your Time

Time efficiency is a core value at My Design Minds. We understand the importance of deadlines, ensuring a quick turnaround time without compromising quality.

Industries We Serve

We serve various industries by providing high-quality molds for different applications. In the automotive sector, we create precision molds for engine parts, interior trims, and lighting components. For consumer electronics, we produce molds for casings, connectors, and circuit board enclosures. In medical and healthcare, our molds are used for surgical instruments, implants, and diagnostic devices. The packaging industry benefits from our molds for food containers, bottles, and caps. We also support the aerospace industry with durable, high-precision molds for aircraft components.

Conclusion

Mould manufacturing is a critical aspect of modern industry, requiring expertise, precision, and the right technology. At My Design Minds, we bring all these elements together to provide world-class moulds tailored to your business needs. Don’t compromise on quality—choose excellence with My Design Minds.