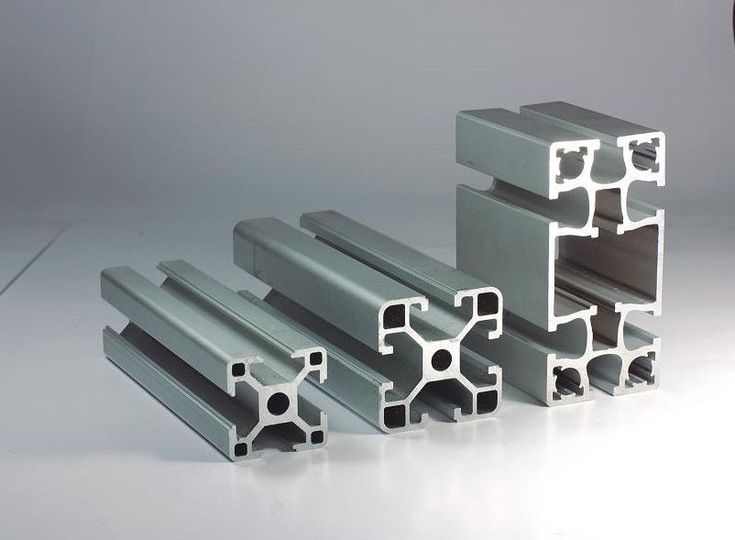

At My Design Minds, We provide high quality of Extrusion Manufacturing to meet the need of industries. We have team of professional , Who have mastered in all types of Extrusion Services, which also allow them to deliver precision-engineered profiles, superior material properties, and cost-effective solutions for a wide range of applications.

What is Extrusion

Extrusion is a manufacturing process where a material (like metal, plastic, or rubber) is forced through a shaped opening (die) to create a continuous profile with a specific shape. Think of it like squeezing toothpaste out of a tube—the material takes the shape of the opening as it comes out. This process is widely used to make products like pipes, window frames, tubing, and even food. There are many types of Extrusion Services provided by My Design Minds :

Hot Extrusion

Hot extrusion is a manufacturing process used to create special steel profiles with a constant cross-section along their length. It works by applying strong compressive force to push heated metal through a shaped die, forming solid or hollow bars in a single step. This method allows for the production of complex shapes with precise dimensions while maintaining a consistent cross-section.

It is mainly conducted at high temperature to make metal easy for work .

Mainly used for materials like aluminum, copper, steel and many more.

Cold Extrusion

Cold extrusion is a process used to shape metal without heating it. It works by striking a metal slug with a punch inside a sealed chamber, forcing the metal to flow upward around the punch. This method is also known as impact extrusion, cold forging, cold pressing, cold extrusion forging, or extrusion pressing. It allows manufacturers to create strong, accurate parts with little material waste.

It is usually performed at room temperature for higher strength and better surface finish.

Most it`s demand come from automotive and aerospace industries.

Direct Extrusion

The most common type of extrusion is direct extrusion, also called forward extrusion. In this process, a metal billet (a solid block of material) is placed inside a strong-walled container. A ram or screw then pushes the billet through a die to shape it into the desired form. To prevent direct contact between the ram and the billet, a reusable dummy block is placed in between, helping to improve efficiency and extend the life of the equipment.

It is suitable for producing solid and hollow profile.

Indirect Extrusion

Indirect extrusion, also called backward extrusion, works by pushing the billet (metal block) and the container together while keeping the die in a fixed position. To hold the die steady, a stem (a long supporting rod) is used, which must be longer than the container. The strength of this stem determines how long the extrusion can be made. This method helps reduce friction, making the process more efficient and requiring less force compared to direct extrusion.

It is mainly preferred for materials that require high-quality surface finishes.

Our Advantages

Experience

My Design Minds have years of experience in Extrusion Manufacturing , Our highly specialized team use advanced technology and technique to satisfy your requirement and will provide you high quality of product.

We have proudly served industries like automobile manufacturing, construction, medical equipment, and consumer electronics by providing customized extrusion solutions that meet the highest quality standards.

Fast Turnaround Times

Our production plant and partners use the latest machinery, allowing us to respond quickly to your needs. We ensure fast delivery of your parts while keeping you updated every step of the way. With our dedicated project managers and customer portal, you can track your order in real time for complete peace of mind.

State-of-the-Art Technology

We use advanced machinery and precision tools to deliver high-quality results with accurate dimensions, smooth finishes, efficient material use, and fast production times. By constantly upgrading our technology and software, we stay ahead of the competition, ensuring our clients get the best extrusion solutions available.

Customization and Precision Engineering

We understand that every project is unique, which is why we specialize in custom extrusion solutions designed to meet your exact needs. Whether you require intricate shapes, hollow sections, or multi-material co-extrusions, we manufacture components with accuracy and attention to detail. Our expertise covers complex die design, multi-step extrusion processes, and post-processing services, ensuring that every product meets the highest quality standards.

Conclusion

Extrusion manufacturing is a critical aspect of modern industry, requiring expertise, precision, and the right technology. At My Design Minds, we bring all these elements together to provide world-class services to your business needs. Don’t compromise on quality—choose excellence with My Design Minds.