Welcome to My Design Minds, your one-stop destination for Mechanical CAD Design services. In today’s world, 3D scan has become an increasingly important tool for businesses looking to improve their product design and development process. In this article, we’ll explore what 3D scanning is and how you can use it to enhance your mechanical CAD design services.

What is 3D Scanning?

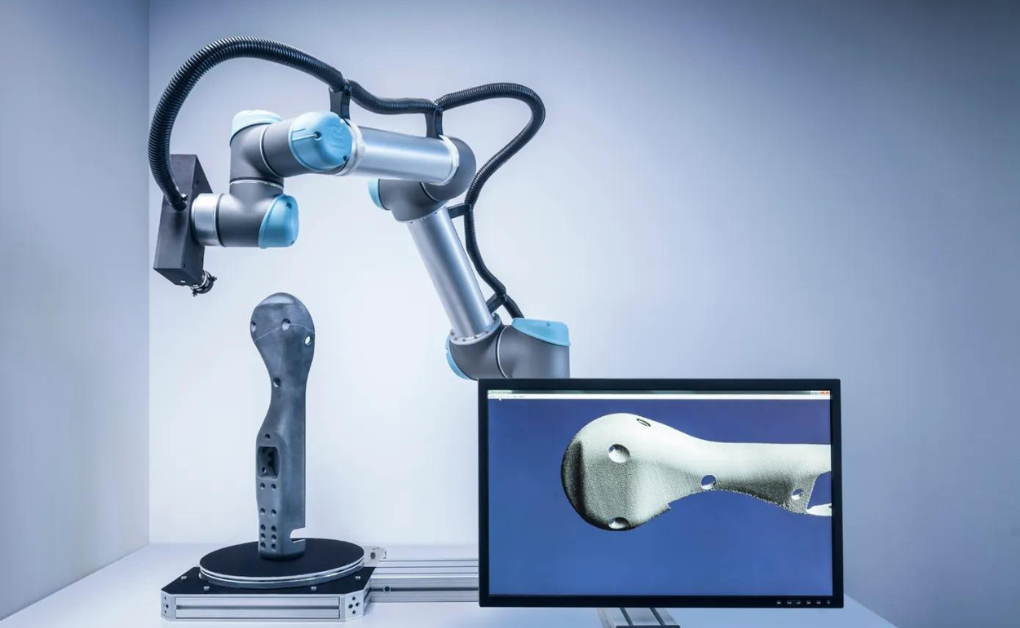

3D scanning is the process of capturing the shape and dimensions of an object using specialized equipment. This equipment uses a variety of methods, including laser scan, structured light scanning, and photogrammetry, to create a detailed 3D model of the object. In the context of mechanical CAD design services, one can use 3D scan to create accurate 3D CAD models of existing parts, modify existing designs, or create new designs from scratch.

How Does 3D Scanning Work?

The 3D scanner works by projecting a beam of light or another energy source onto the object it needs to scan. Then, the scanner reflects the energy back and analyzes it to create a 3D model of the object. The scanner captures millions of data points to create a detailed digital representation of the object. Then, we can import this digital model into a CAD program, where we can modify, optimize, or improve it.

Benefits of 3D Scanning for Mechanical CAD Design Services

3D scan offers several benefits for businesses looking to improve their mechanical CAD design services. These include:

- Increased Design Accuracy: 3D scanning allows designers to capture the exact dimensions and shape of existing parts, reducing the risk of errors and ensuring that new designs fit perfectly with existing components.

- Faster Design Process: 3D scanning can speed up the design process by providing a starting point for new designs. Designers can modify existing designs rather than starting from scratch, which can save time and reduce errors.

- Cost Savings: 3D scanning can also lead to cost savings by identifying ways to improve existing designs, reducing material waste, and optimizing the manufacturing process.

How Does 3D Scanning in Mechanical CAD Design Work?

The process of 3D scanning services in delhi (in mechanical CAD design) typically involves the following steps:

- Setting up the Scanner: The first step is to set up the 3D scanner and calibrate it for the object being scanned. This involves configuring the scanner’s settings, such as the resolution and scan speed.

- Scanning the Object: Once you set up the scanner, scan the object from multiple angles to capture its geometry and dimensions. The scanner generates a point cloud of the object, which is a set of three-dimensional data points that represent the object’s surface.

- Generating a Digital Model: The point cloud is then processed by specialized software that converts it into a digital 3D model. The model can be edited and refined using mechanical CAD software to optimize its design.

- Finalizing the Design: Once the digital model is complete, we can analyze and refine it to ensure that it meets the desired specifications and quality standards.

Conclusion

At My Design Minds, we understand the importance of 3D scanning services in delhi in mechanical CAD design services. Our team of experienced designers and engineers has the knowledge and expertise to use the latest 3D scan techniques to improve your product design and development process. Contact us today to learn more about our services and how we can help you take your designs to the next level.