Introduction:–

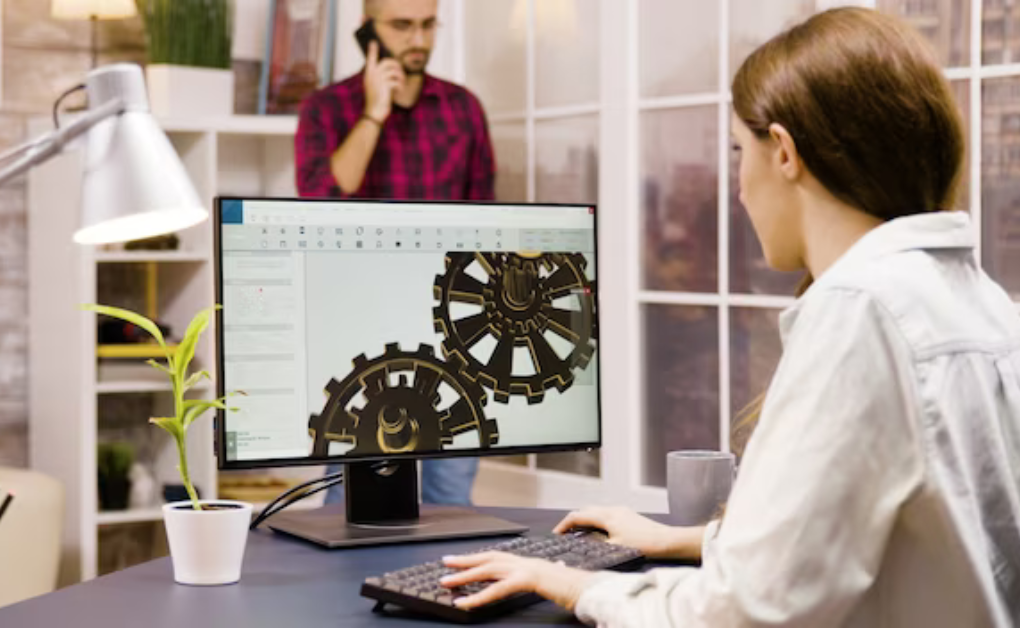

Exploring :-Mechanical CAD Design, With the evolution of technology, the field of product design has transformed significantly over the years. One of the pivotal tools that have enabled this transformation is Mechanical Computer-Aided Design (CAD). In this blog, we will delve into various subcategories of mechanical CAD design and explore their benefits and features.

Plastic Product Design

Plastic product design in CAD involves creating 3D models and drawings for plastic components. The benefits of this approach include:

- Material Optimization: CAD allows designers to choose the right plastic material for the product, considering factors like strength, durability, and cost.

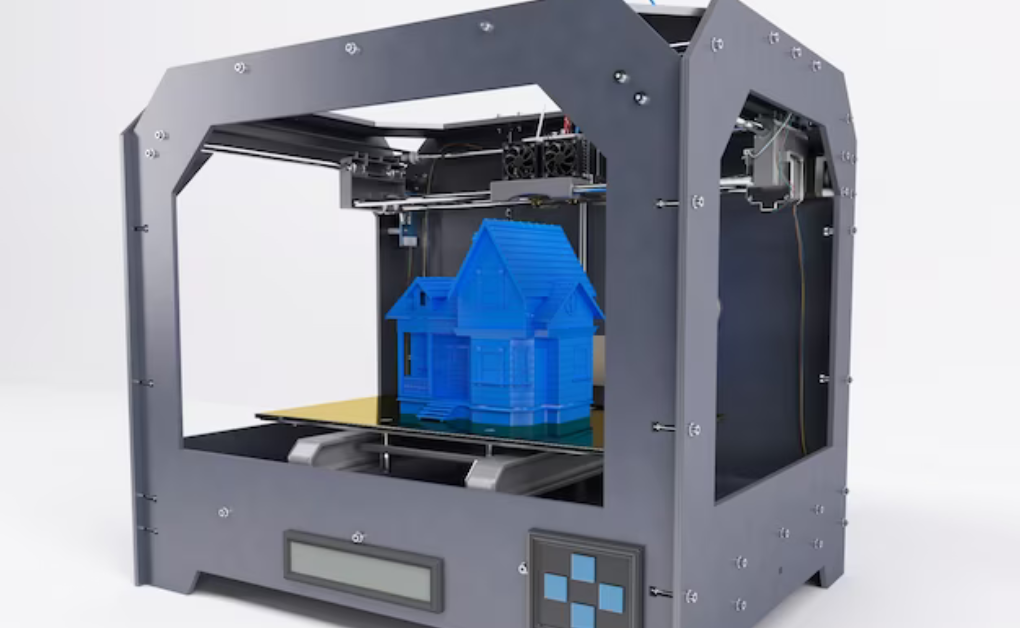

- Prototyping: Rapid prototyping is simplified with CAD, enabling designers to test and refine plastic product designs quickly.

- Complex Shapes: CAD software can handle complex geometries, facilitating the design of intricate plastic components.

Sheet Metal Product Design

Sheet metal product design focuses on designing parts made from thin sheets of metal. Key benefits are:

- Material Efficiency: CAD assists in optimizing sheet metal layouts to minimize waste.

- Cost Reduction: Designers can simulate the manufacturing process, helping to reduce production costs.

- Assembly Design: CAD enables designers to create accurate assembly instructions for sheet metal products.

Part Design

Part design is the foundation of mechanical CAD.

- Parametric Modeling: CAD software allows for parametric design, making it easy to modify parts without starting from scratch.

- Tolerance Analysis: Precise control over tolerances and clear documentation of part specifications.

New Product Development

New product development in CAD involves creating innovative designs from scratch.

- Concept Modeling: CAD enables designers to quickly visualize and iterate on concepts.

- Collaboration: Collaboration tools in CAD streamline communication between design teams.

Special Purpose Machine Design

Designing special-purpose machines requires specific features:

- Kinematic Simulation: CAD software can simulate the machine’s movements and functions.

- Interference Detection: Identify and resolve design clashes before manufacturing.

Mold Design

Mold design is vital for manufacturing plastic or metal parts.

- Cavity and Core Design: Precise mold cavity and core design for high-quality parts.

- Cooling Analysis: Optimization of cooling channels for efficient production.

Industrial Product Design

Designing industrial products demands attention to detail:

- Ergonomics: CAD assists in optimizing product ergonomics for user comfort.

- Material Selection: Choosing the right materials for durability and functionality.

CAD File Conversions

CAD file conversions are essential for compatibility.

- File Format Compatibility: Convert between various CAD file formats for seamless collaboration.

- Data Integrity: Ensure data integrity during conversions to prevent errors.

2D Drafting

2D drafting is still essential for manufacturing documentation:

- Dimensioning: Accurate dimensioning tools for clear and concise drawings.

- Annotations: Add notes and labels to clarify design intent.

Assembly and Fitment Check Analysis

Assembling parts correctly is crucial. CAD offers:

- Assembly Tools: Easily assemble complex products virtually to check for fitment.

- Interference Detection: Detect and rectify assembly interferences.

My Design Minds: Your CAD Design Solution

My Design Minds is a leading player in the field of mechanical CAD design. With decades of experience, we offer comprehensive services in all the aforementioned subcategories of CAD design. Our team of experts leverages cutting-edge CAD software to provide:

- Tailored Solutions: We customize our services to meet your specific needs, whether it’s prototyping, new product development, or CAD file conversions.

- Cost-Effective Designs: Our design strategies prioritize cost-efficiency without compromising on quality.

- Efficient Collaboration: We facilitate seamless collaboration throughout the design process, ensuring your ideas are incorporated into the final product.

- Quality Assurance: Rigorous quality checks and fitment analysis to ensure error-free designs.

Common User Queries-

- Can CAD design really save on production costs? Absolutely. CAD enables precise material and process optimization, reducing wastage and production errors.

- How long does it take to develop a new product using CAD? The timeline varies depending on complexity, but CAD significantly reduces design iteration time, making the process faster.

- What CAD formats are compatible with My Design Minds? We support a wide range of CAD formats, ensuring compatibility with your existing tools and systems.

Mechanical CAD design has revolutionized product development, and its subcategories offer a wealth of benefits. My Design Minds stands ready to assist you with all your CAD design needs, delivering cost-effective, efficient, and high-quality solutions. Hope now you can Exploring :-Mechanical CAD Design easily.